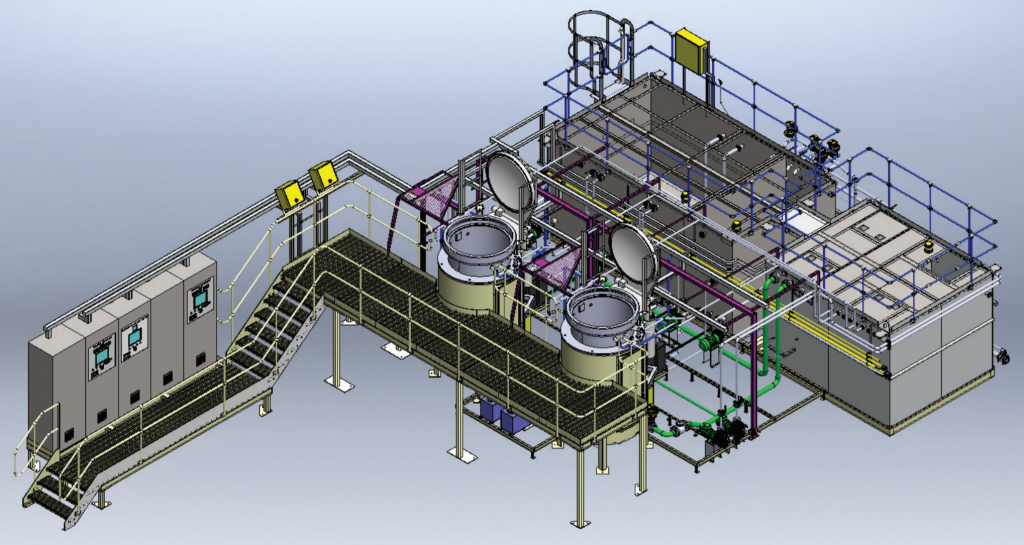

SPEC’s client started up a new caustic leaching autoclave and required assistance to refine the leach/etch finishing process. SPEC was brought on to operationalize the leach system, which expanded into troubleshooting the leach process to improve the removal of the ceramic core from the product through experimental iteration, while training operators, creating SOPs, and developing the record-keeping system. SPEC aided the lab-scale acid etch process with troubleshooting to attain consistent results, then designed and provided procurement support for the pilot-scale etch process. The leach and etch processes were designed to be housed in an annex building; SPEC reviewed a third-party engineering design for the annex, including ventilation for exposure control from caustic and acid fumes, as well as designed a water scrubber to treat fumes and vapors.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Safety, Procurement Support.

Client: Industrial Manufacturing Company

Location: Northeast, USA