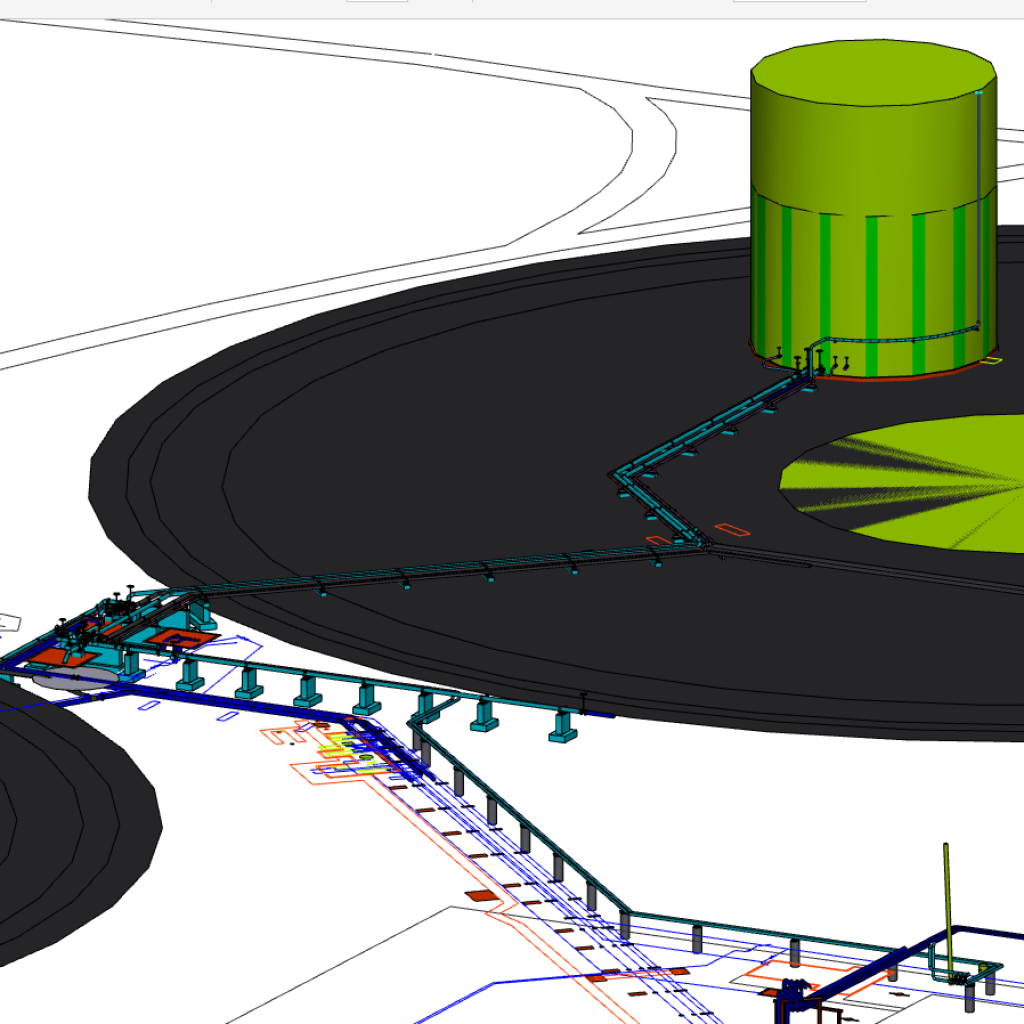

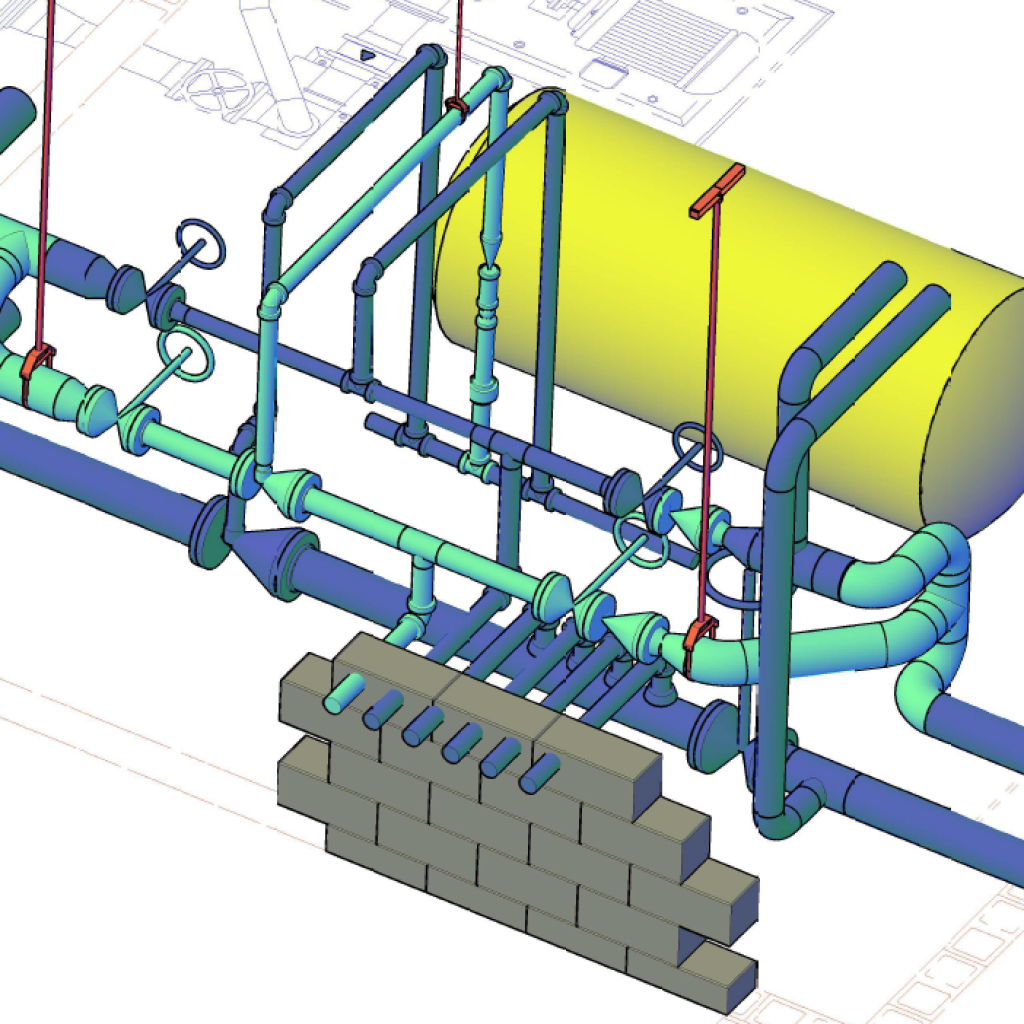

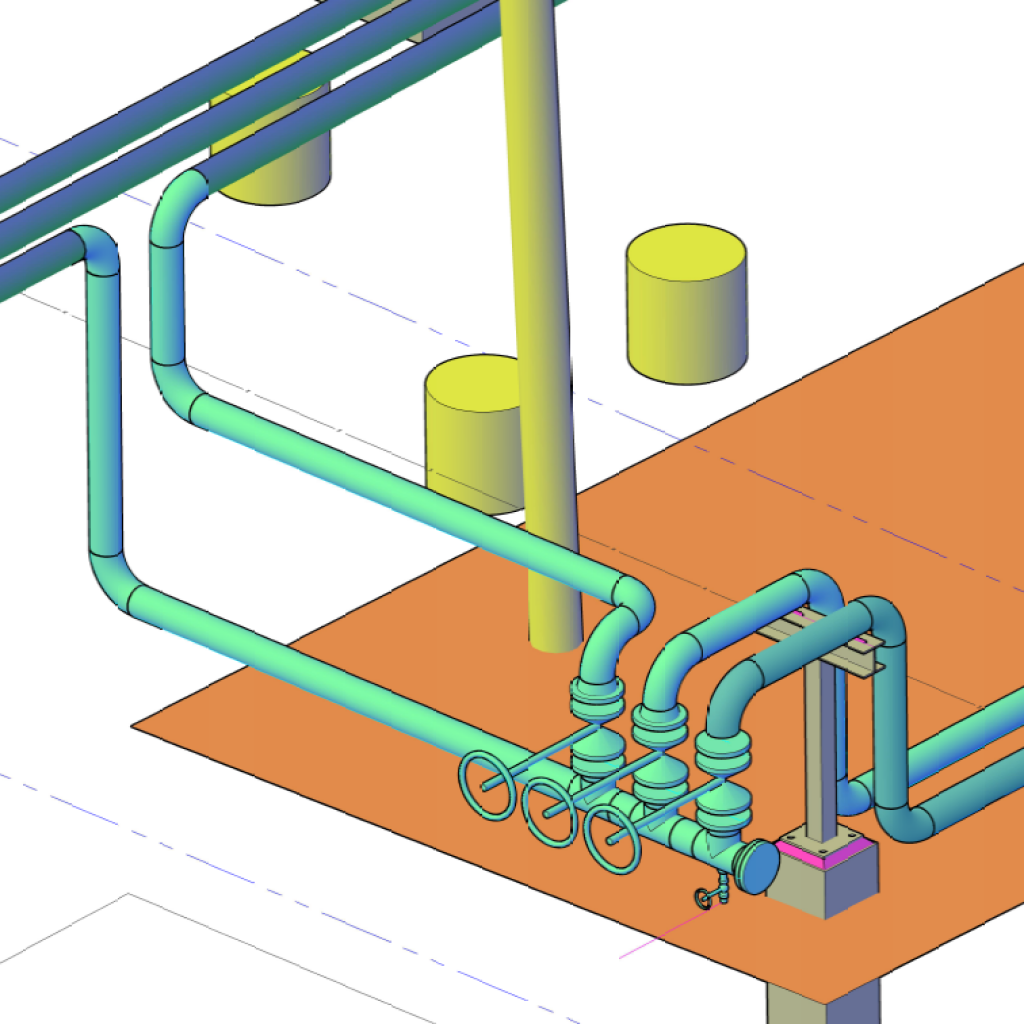

SPEC provided support to modify the existing foam-water system at a Client’s truck loading terminal. The project goal was to increase capacity to provide fire protection for a new tank and provisions for a future new tank. Design work included evaluating current system capability, sizing a new mixing valve and tank foam chamber, modifying the existing piping arrangement in the foam house, adding an external manifold, and routing piping to the new tank. SPEC completed the mechanical and civil design of the foam-water fire piping modifications, design of pipe supports in a flood prone area, and generation of construction drawings and modified P&ID.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Mechanical Engineering, Design and Drafting, Scanning and 3D Modeling, Fire Protection, Procurement Support.

Client: Major Oil Company

Project Location: Southwest, USA