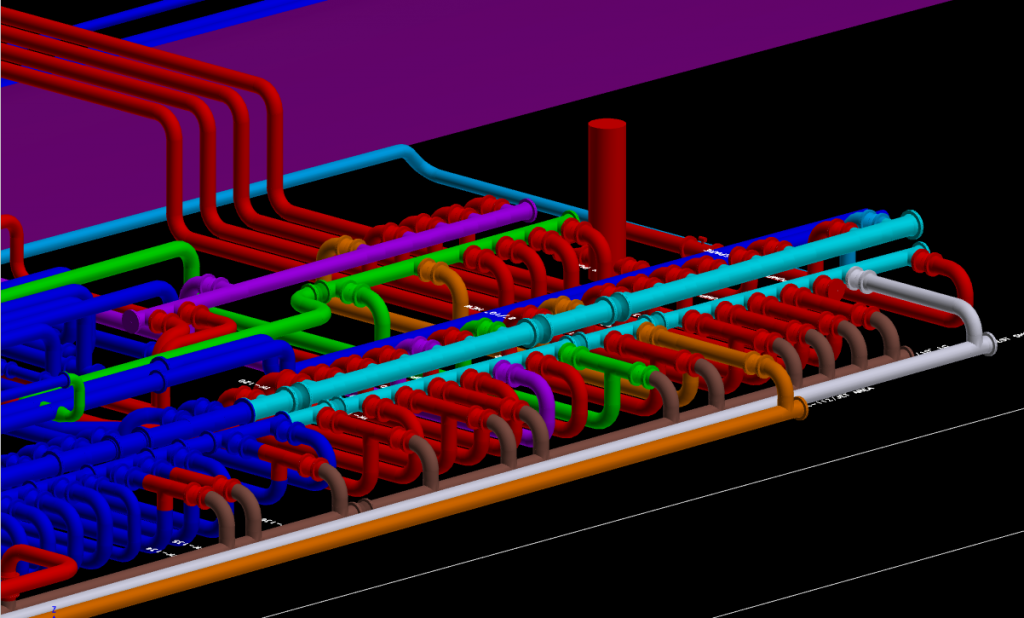

SPEC provided support for the expansion of the infrastructure at a recently purchased terminal to increase connectivity between various refinery tank farms and to provide additional capacity to blend stock components and move finished products. The scope of work included definition of the overall project, verifying the existing piping and equipment on the site, permitting, performing system hydraulics to size (11) new pumps and (3) small volume provers, construction of (4) new 150 KB storage tanks complete with butane and gasoline blending equipment, associated tank containment dikes, the addition of over (3) miles of new internal terminal pipelines, expansion of a large central manifold, two sets of directional drilled pipelines under canals, additions of various tie-ins and cross-connects, and electrical upgrades. SPEC used a portable laser scanner to quickly provide the client with 3D models of the site layout.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Electrical Engineering, Instrumentation and Controls, Mechanical Engineering, Design and Drafting, Scanning and 3D Modeling, Permitting, Safety, Fire Protection, Procurement Support, Construction Management.

Services included overall project management, mechanical, civil, and electrical design of the terminal expansion, and procurement support including equipment specification, bid analysis, and tracking of over 240 automated and manual valves.

Client: Major Oil Company

Project Location: Midwest, USA