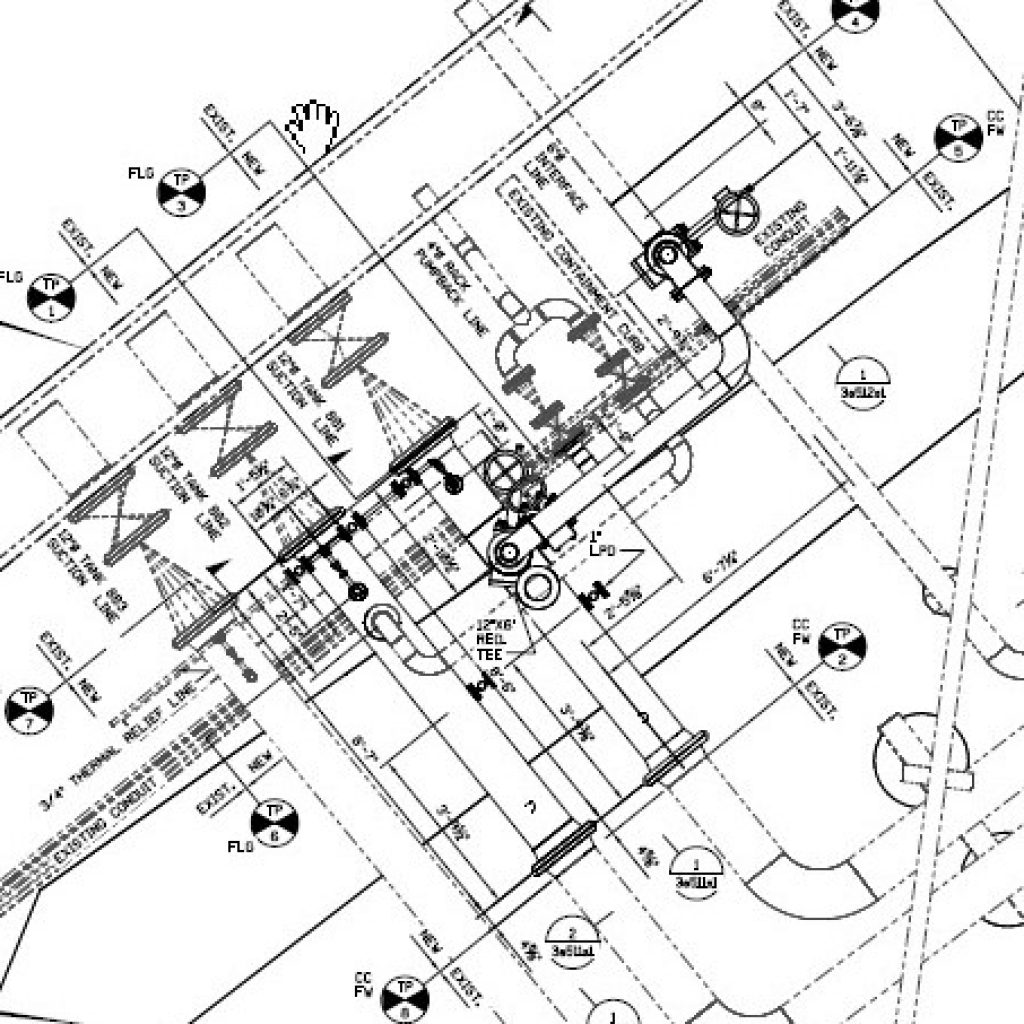

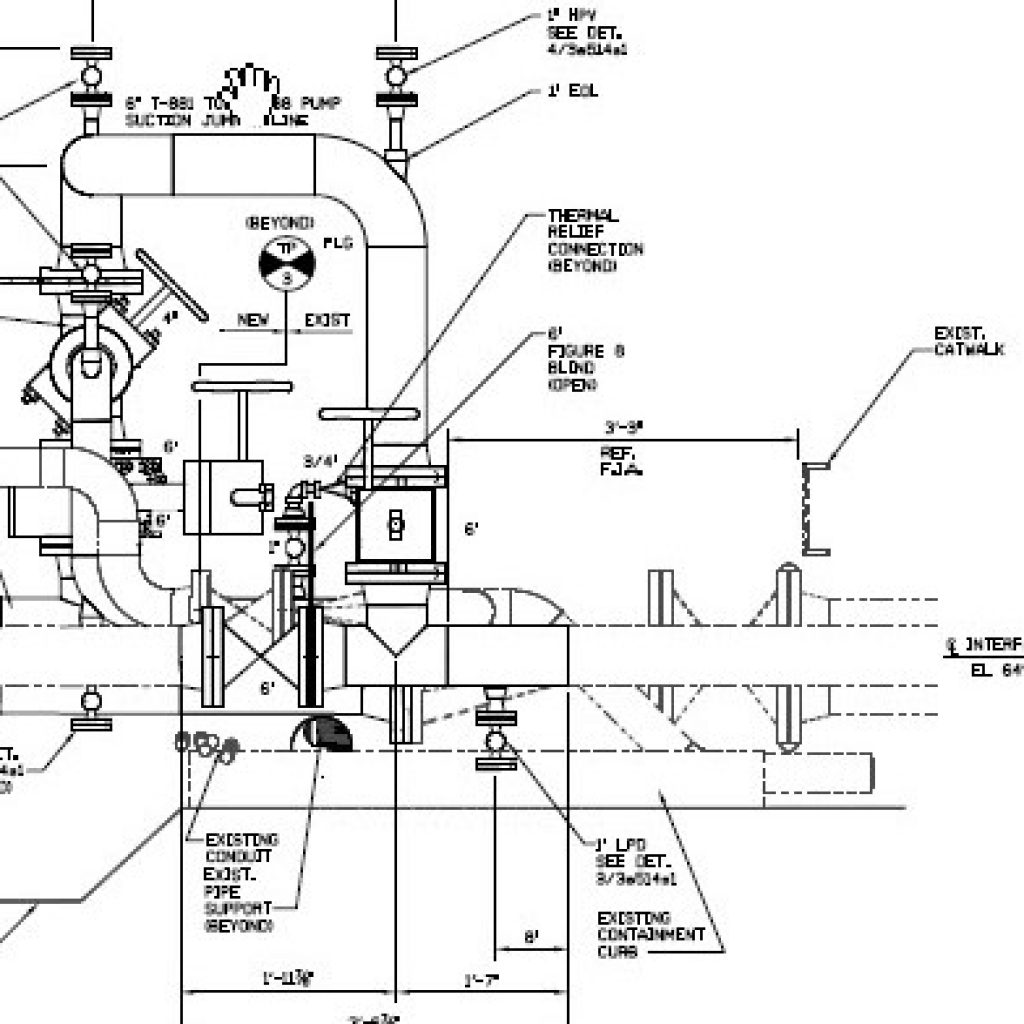

SPEC provided support for the modification of terminal piping to allow for an existing regular gasoline tank to be used as a pipeline interface swing tank during the interface tank inspection at a distribution terminal. SPEC designed a new pipe spool piece and isolation valves to allow for tank loading to the load rack at the new swing tank. SPEC performed 3D laser scanning of existing piping and equipment, stress analysis for new pipe spools, and created project record drawings. SPEC’s design enabled the use of the existing tank for interface storage, allowing the terminal to meet the deadline for the existing interface tank inspection.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Mechanical Engineering, Design and Drafting, Scanning and 3D Modeling, Procurement Support

Client: Major Oil Company

Project Location: Southwestern, USA