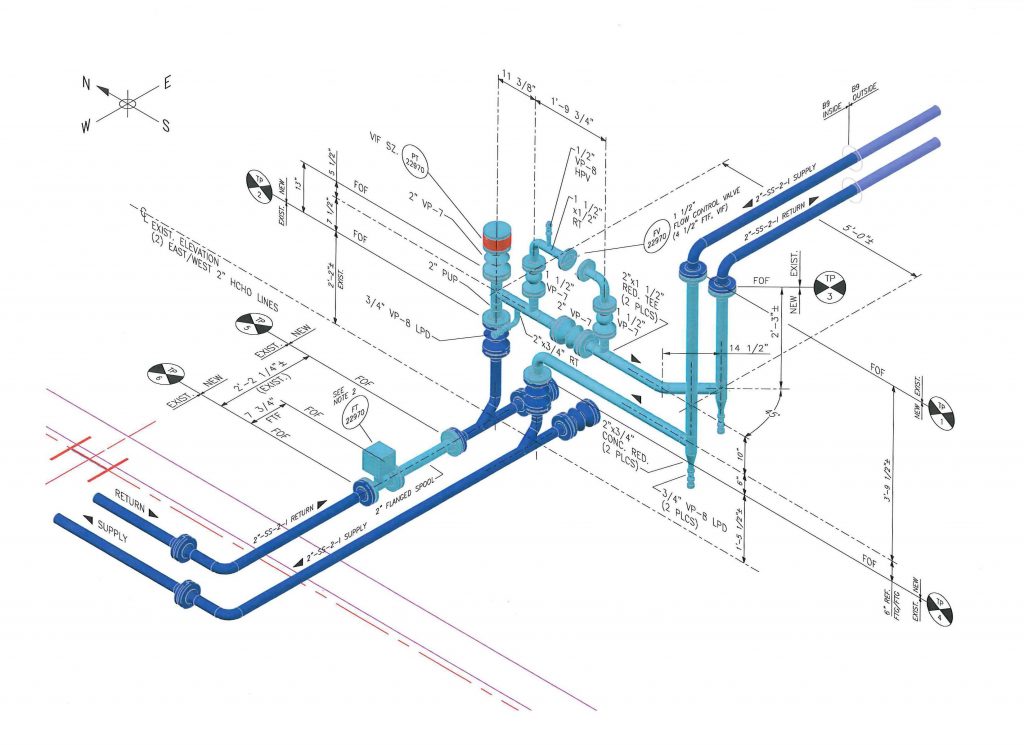

SPEC provided engineering support for safety upgrades to an existing reactant delivery system. The existing system had the potential to add reactant too quickly, which could lead to runaway reactions. SPEC’s evaluation of the process identified that the installation of two pressure control valves on the reactant loop and installation of restriction plate orifices at each reactor created functional safety for the system by physically limiting the addition rate below the runaway reaction threshold without crippling production rates. With the relatively minor changes, flow was limited to 100% design flow rates under ideal conditions and only limited to 90% design flow rates under less-than-ideal conditions. SPEC was able to provide our client with a significantly more economical option that was installed within several months, rather than waiting more than a year for a full duplicate backup control system and instrumentation.

Services Provided: Project Management and Design, Process Engineering, Instrumentation and Controls, Mechanical Engineering, Safety, Procurement Support, Construction Management

Client: Major Chemicals Company

Project Location: Northeast, USA