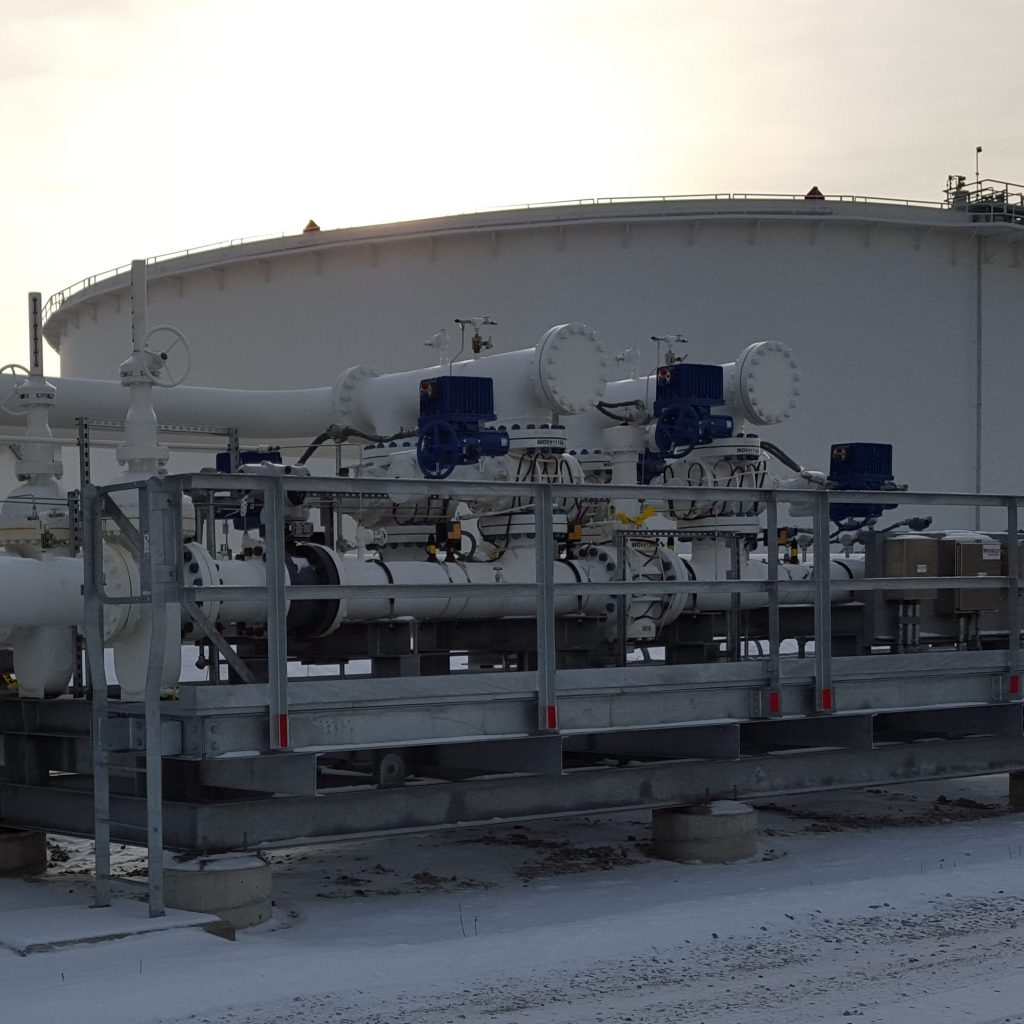

SPEC provided the engineering and construction support for the installation of four new 200-foot diameter agitated tanks at a client’s terminal. SPEC’s scope included permitting in a wetlands area, tie-in to a pipeline manifold, installation of new mainline pumps, tank agitators, custody transfer quality flow meters, meter prover and electrical building in addition to the installation of the new tanks. The new tanks served as backup supply of crude oil to feed a refinery in the event of a pipeline supply outage.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Electrical Engineering, Instrumentation and Controls, Mechanical Engineering, Design and Drafting, Permitting, Safety, Fire Protection, Procurement Support, Construction Management

Client: Major Oil Company

Project Location: Midwest, USA