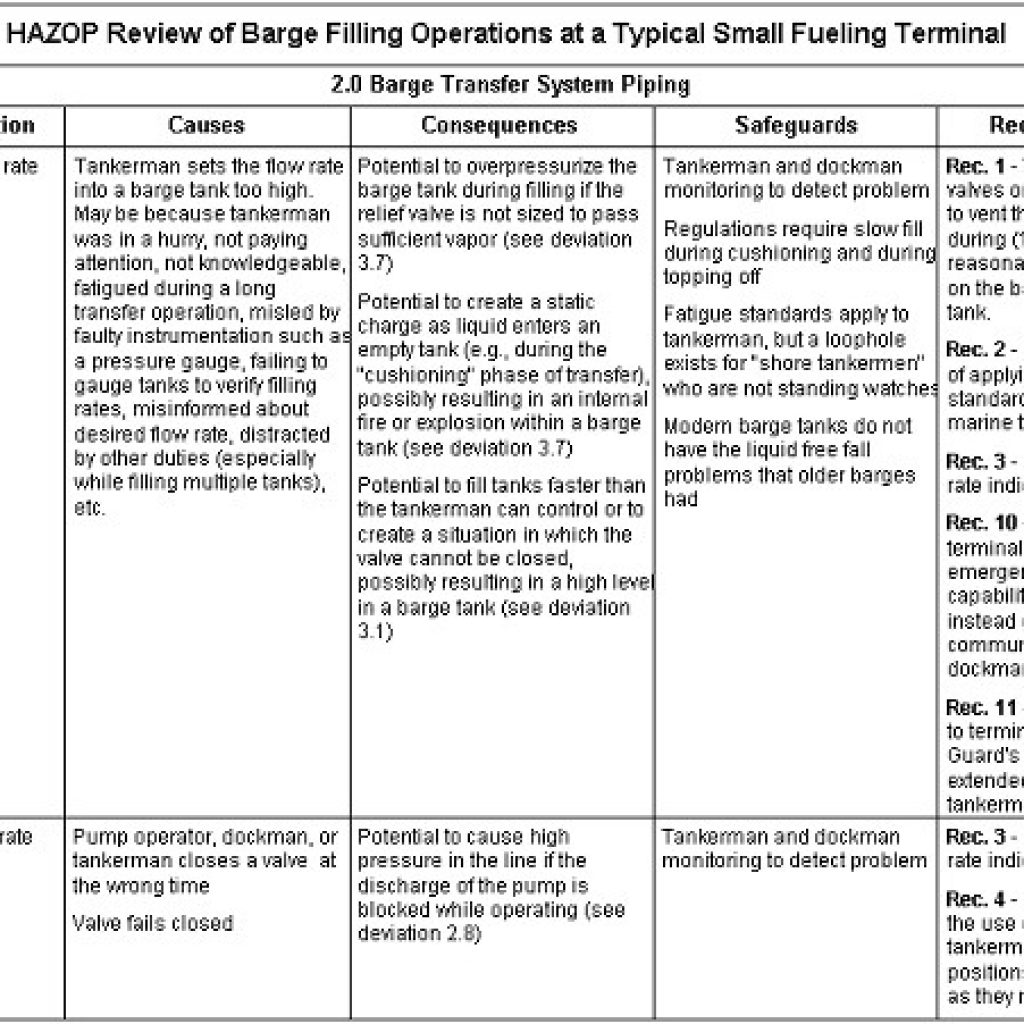

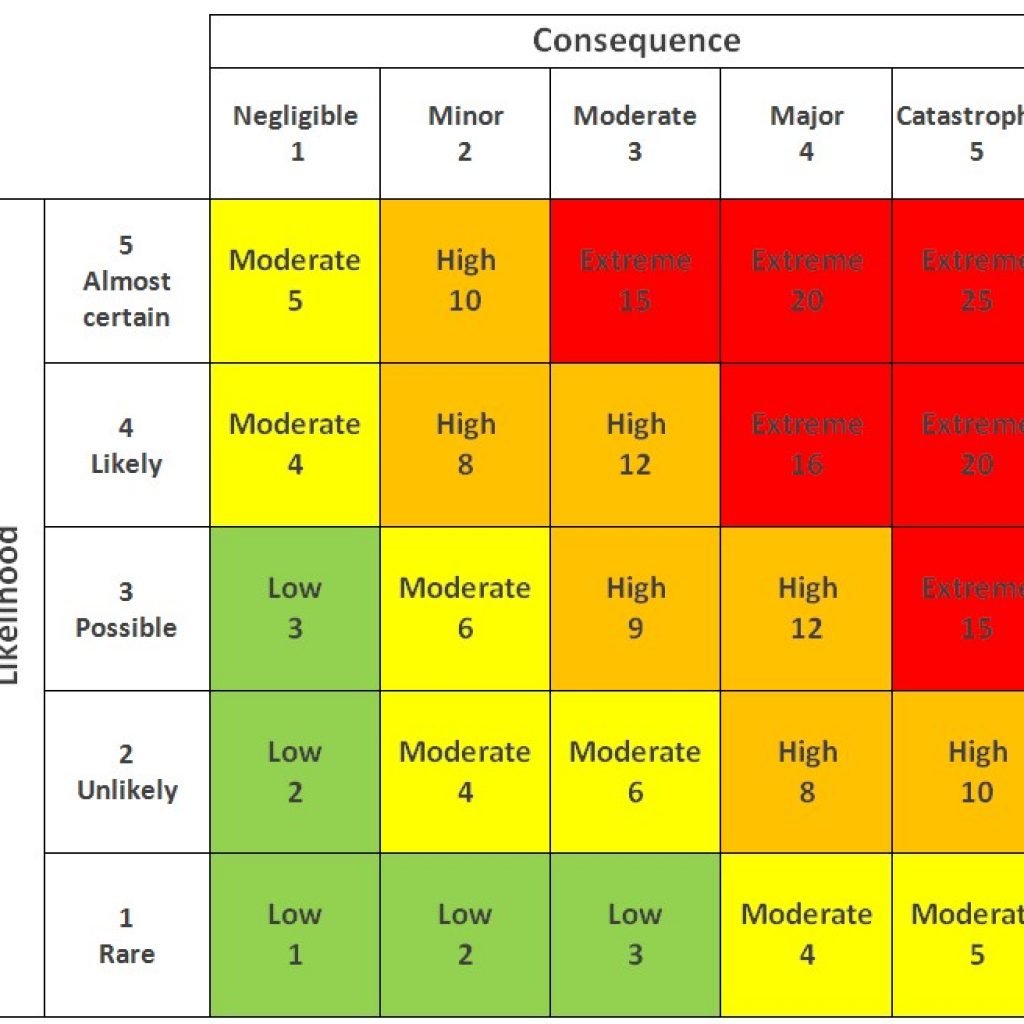

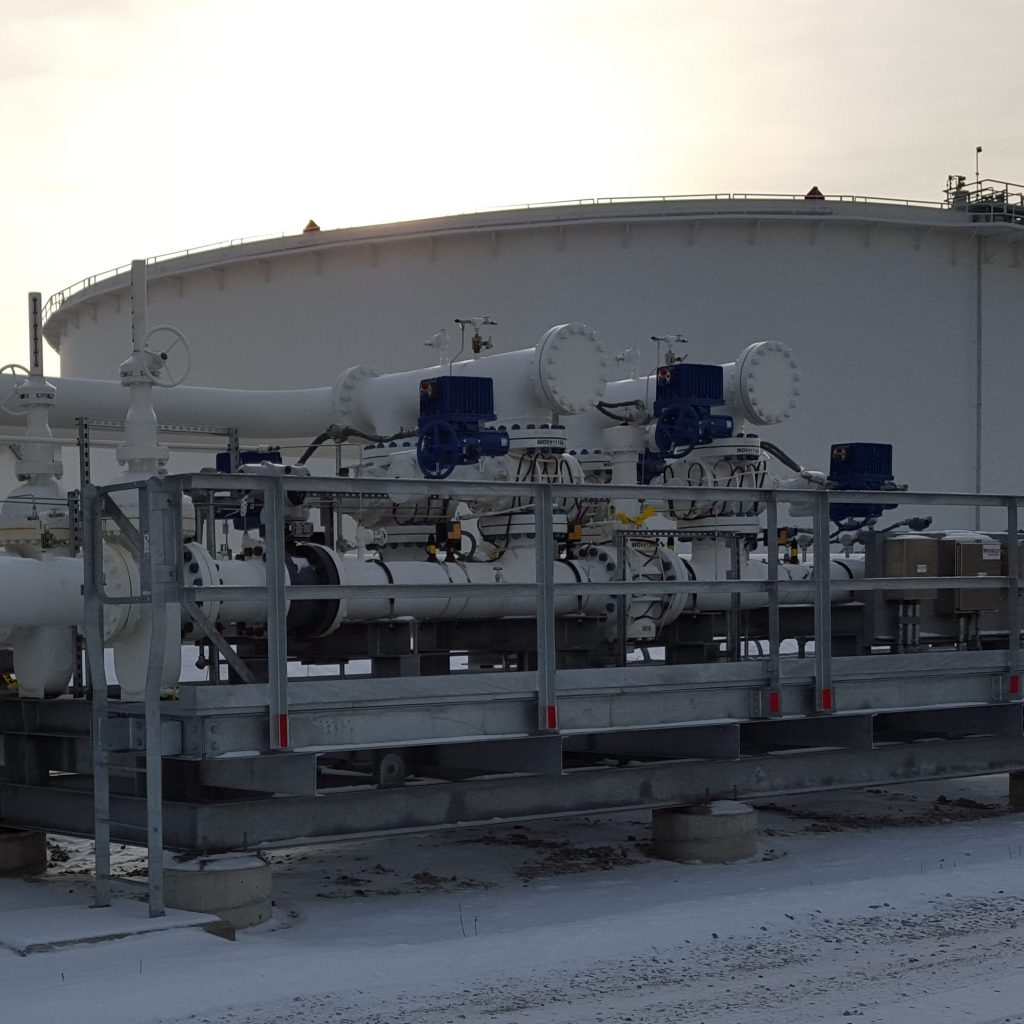

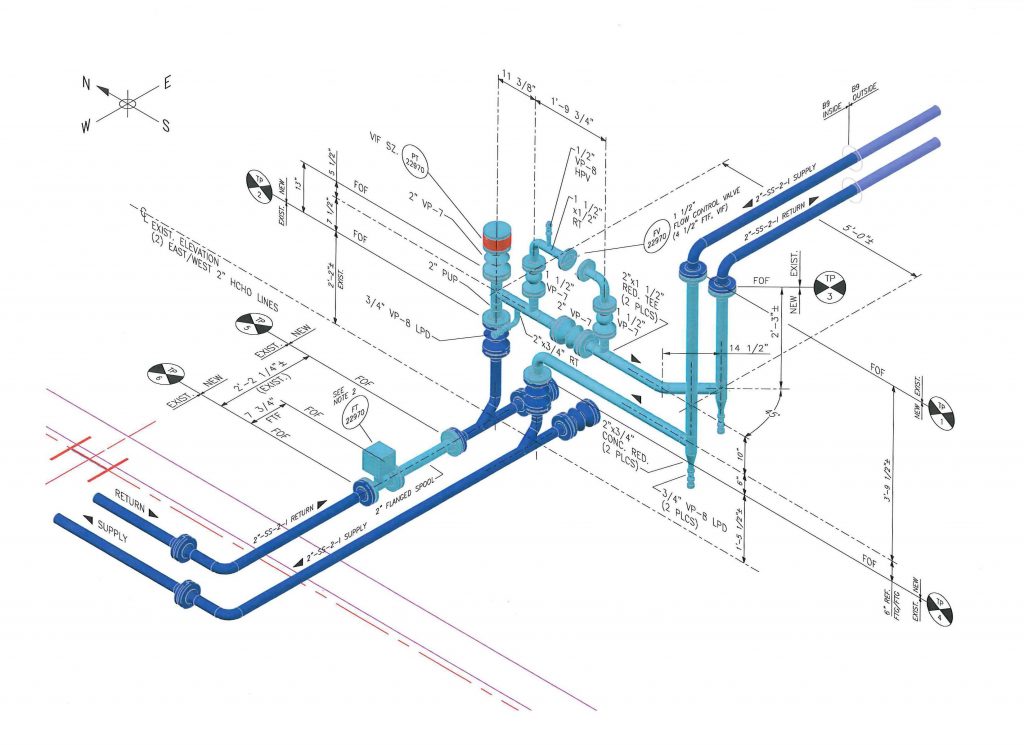

SPEC provided client certified Hazard and Operability Study (HAZOP) and Scenario-Based Risk Assessment (SBRA) facilitation services on pipeline and terminal projects throughout the US. The facilitators were senior SPEC employees highly knowledgeable in the design and operation of storage and pipeline facilities. The facilitator’s job was to develop a pre-review charter, perform a readiness review with the client risk group, obtain client sponsor approvals, provide documentation to the team members prior to the review, facilitate the HAZOP or SBRA and produce a report after team approval of the findings. HAZOP facilitation services were performed for capital projects, process changes, and 5-year site wide reviews. SBRA facilitation services were performed for evaluation of specific deviations from standards or for items identified in the field as a potential risk.

Services Provided: HAZOP and Risk Assessment Facilitation

Client: Major Oil and Chemical Companies

Project Location: Continental USA