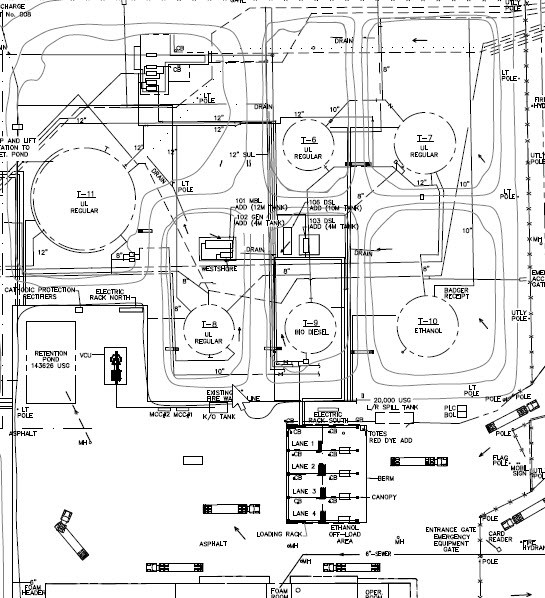

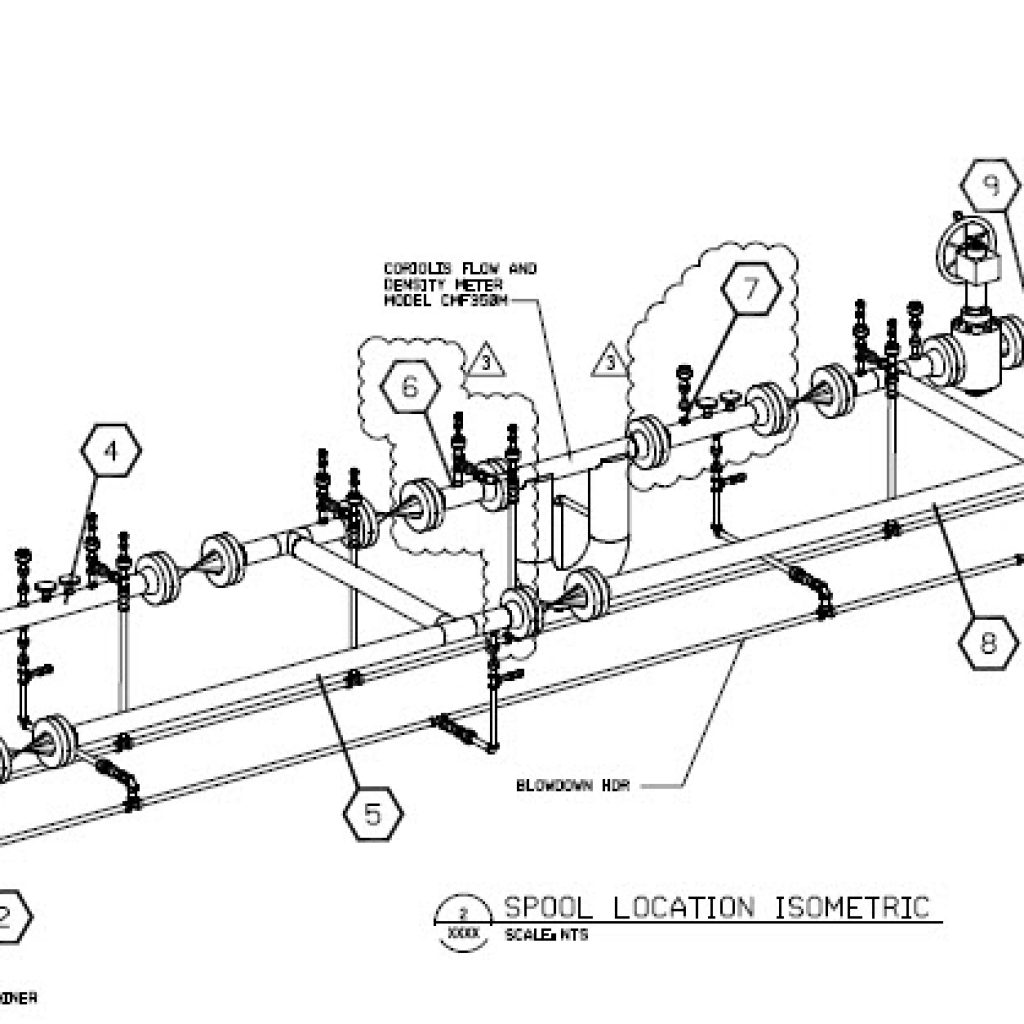

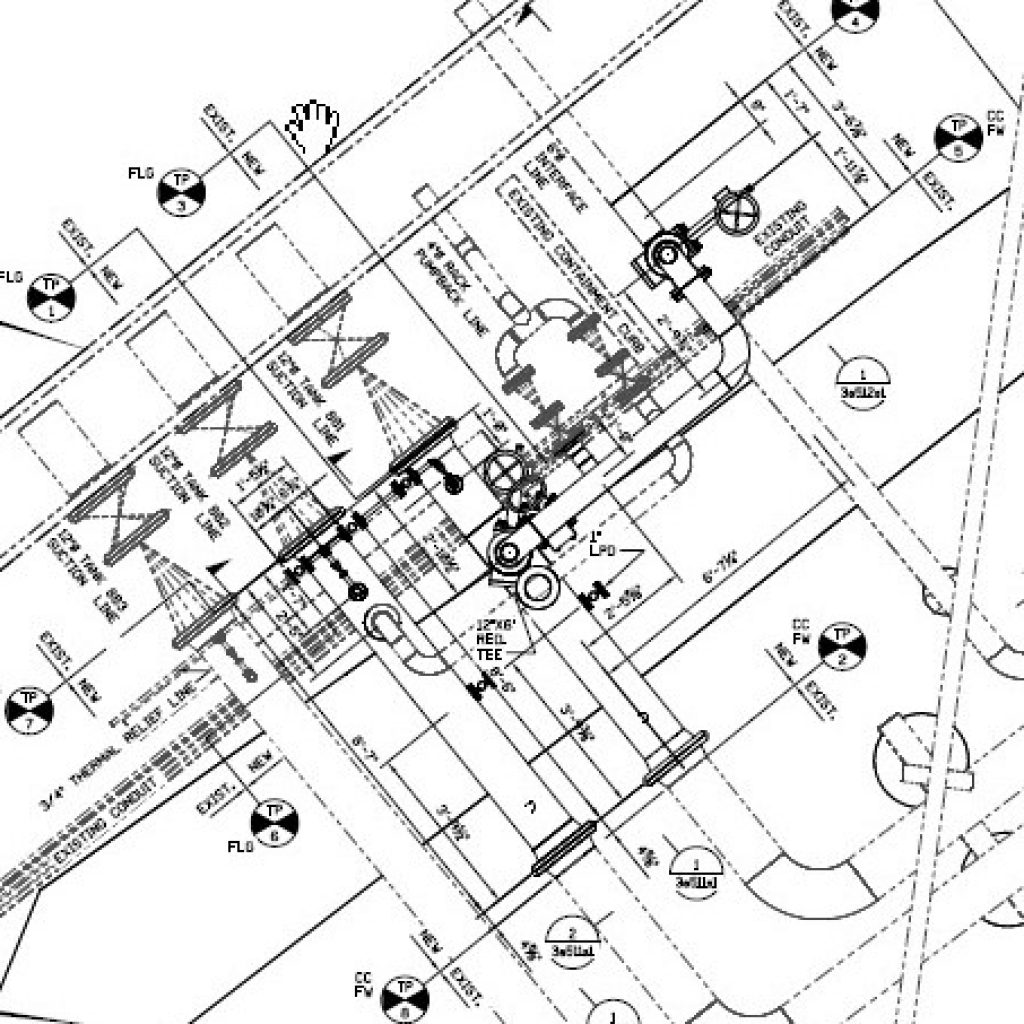

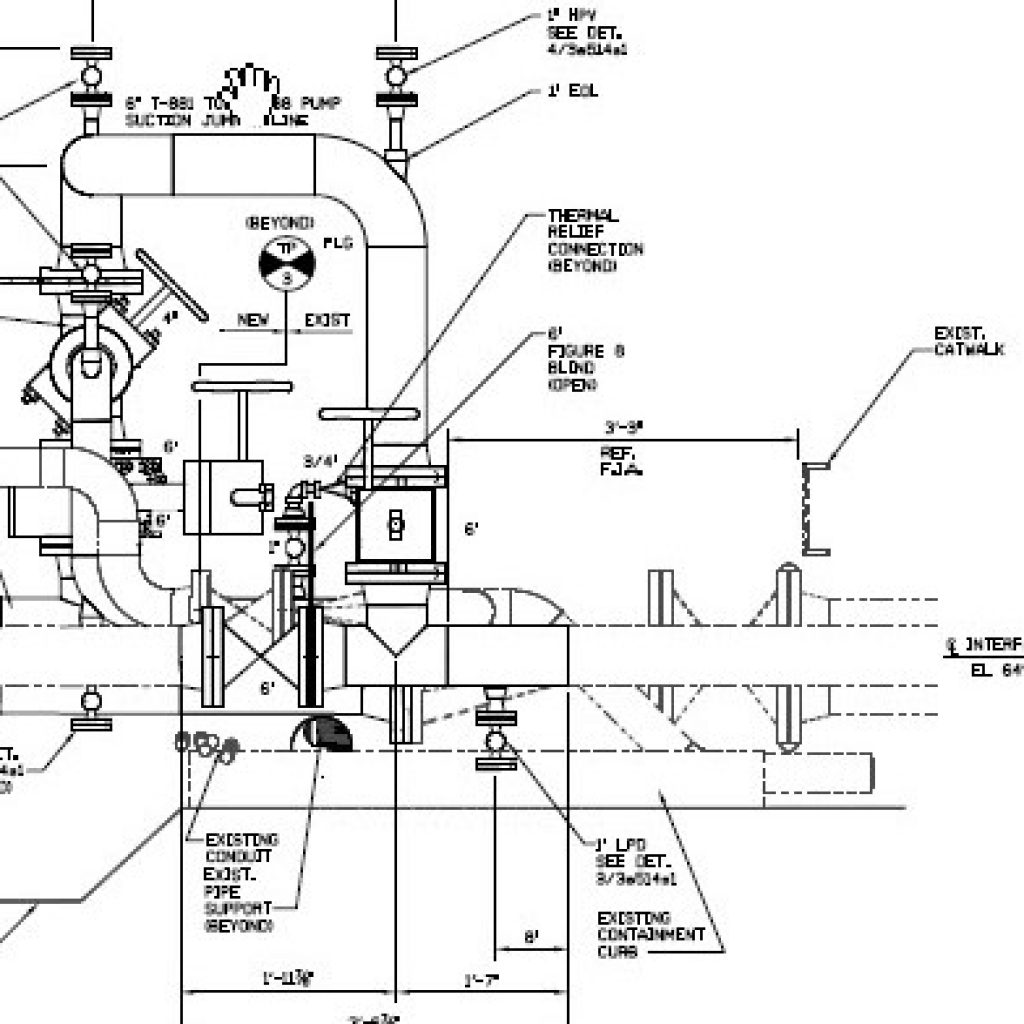

SPEC provided project development, engineering, permitting, drafting, procurement and construction support for the installation of two ethanol storage tanks and a new rail system for bringing in ethanol. SPEC’s scope included design of the rail system, installation of the new tanks and associated pumps, and construction oversight.

Services Provided: Project Development, Engineering, Design, Procurement, Construction Support and Permitting

Client: Major Oil Company

Project Location: Midwest, USA