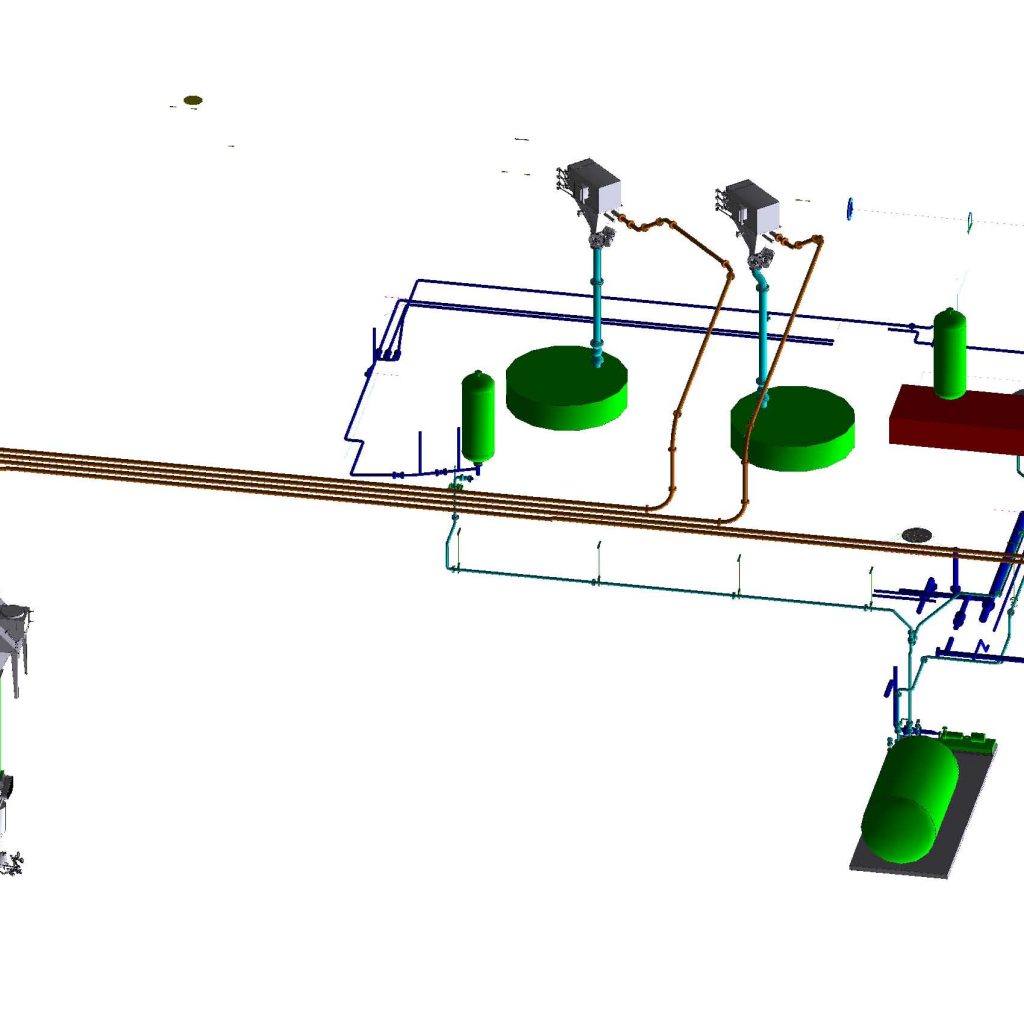

SPEC provided Professional Engineering Services for the civil / structural design of elements of an LNG Export Facility. SPEC served as the Engineer of Record for structural design of the filter house and compressor supporting structures. The equipment was supplied by our client, an Oil & Gas Equipment Supplier and Services Company. We interfaced with the project EPC and local Authority Having Jurisdiction (AHJ) regarding their requirements for structural PE-sealed packages for the Federal Energy Regulatory Commission (FERC) and the local municipality. SPEC performed a detailed review of the equipment structural support requirements and, in conjunction with the client, prepared engineering drawings, basis of design documentation, technical specifications and calculation packages as required by FERC and the local AHJ. The scope included structural steel and steel connection design, pipe and equipment supports, stairways and platforms, and connections / reactions to structural steel columns and foundations designed by the EPC. SPEC performed design calculations using 3D structural software for the structural frame calculations.

Services Provided: Project Management and Design, Civil/Structural Engineering

Client: Oil & Gas Equipment Supplier and Services Company

Project Location: Southwest, USA