SPEC provided project development, engineering, permitting, drafting, and procurement support for the modernization of an older terminal. SPEC was brought in at the beginning of the project to develop initial scoping, perform feasibility studies, and develop cost estimates and schedules.

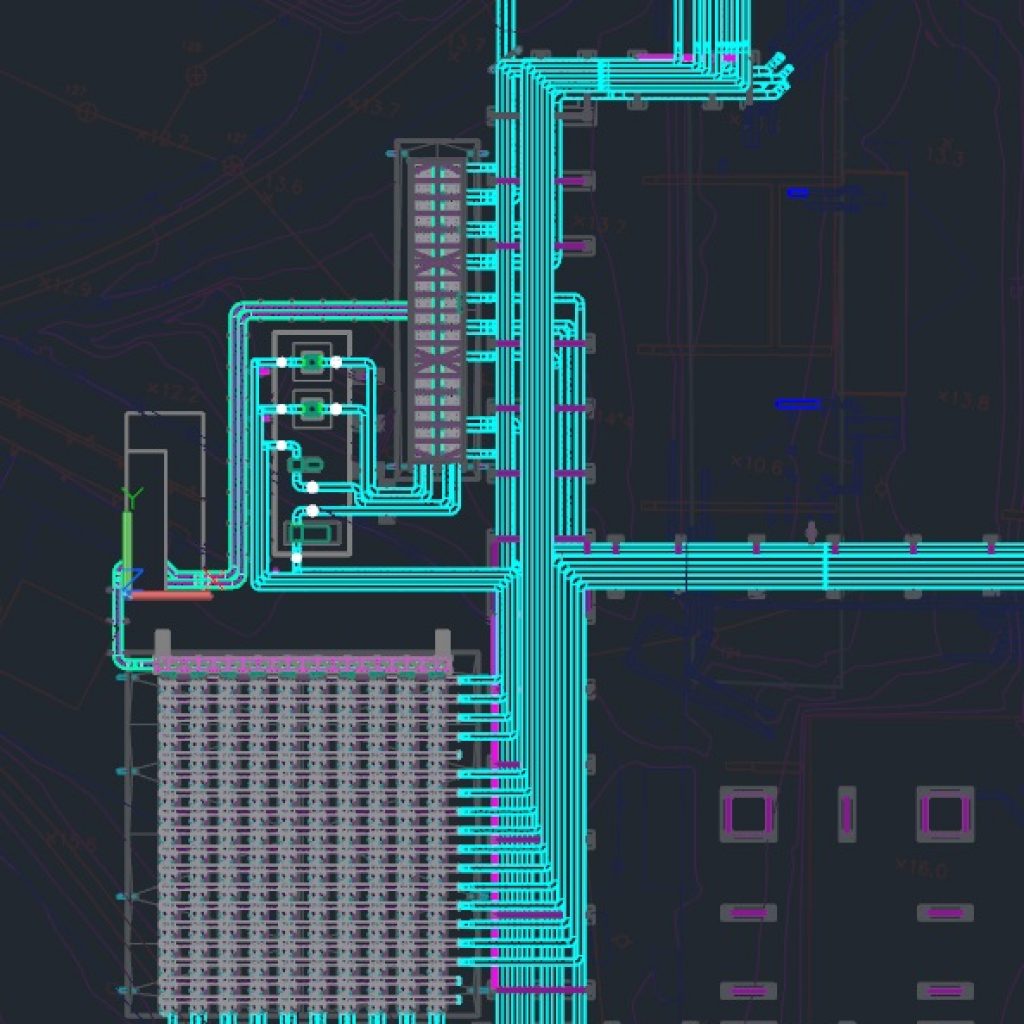

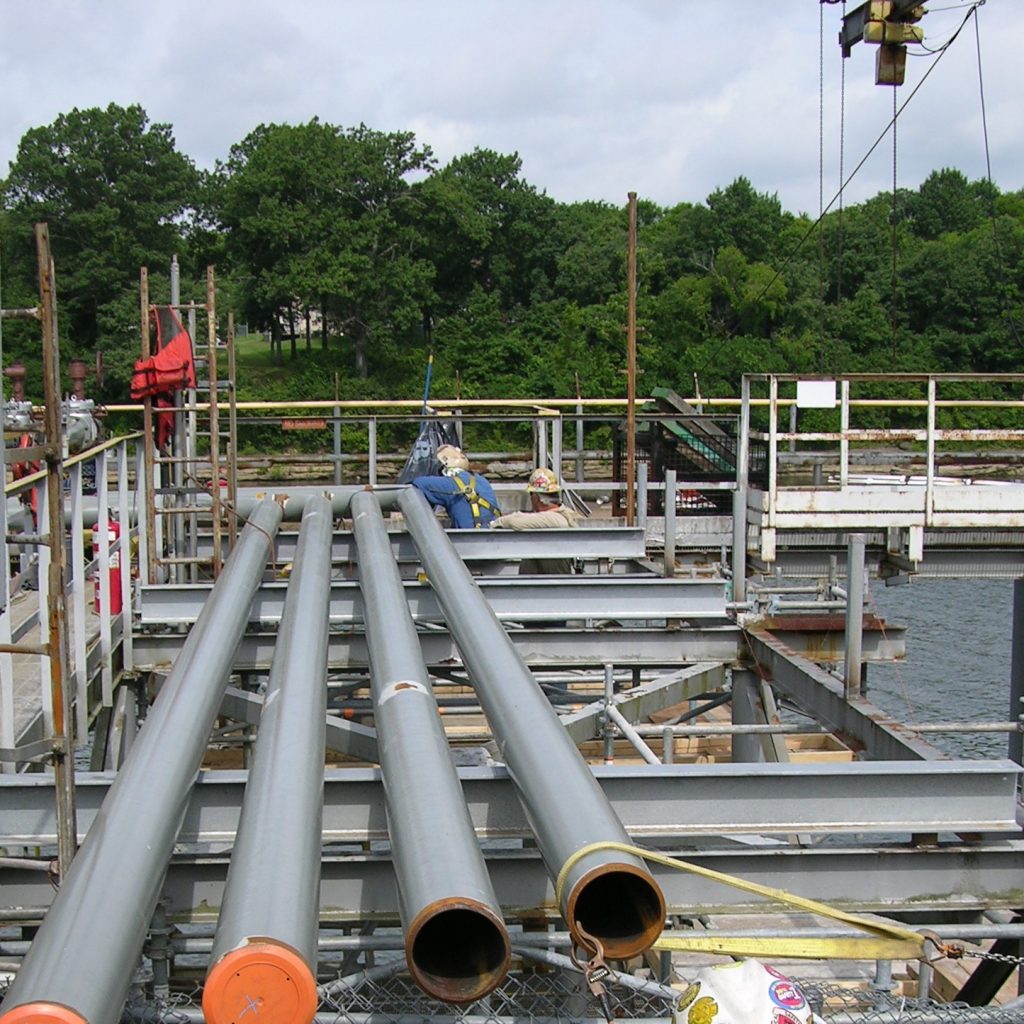

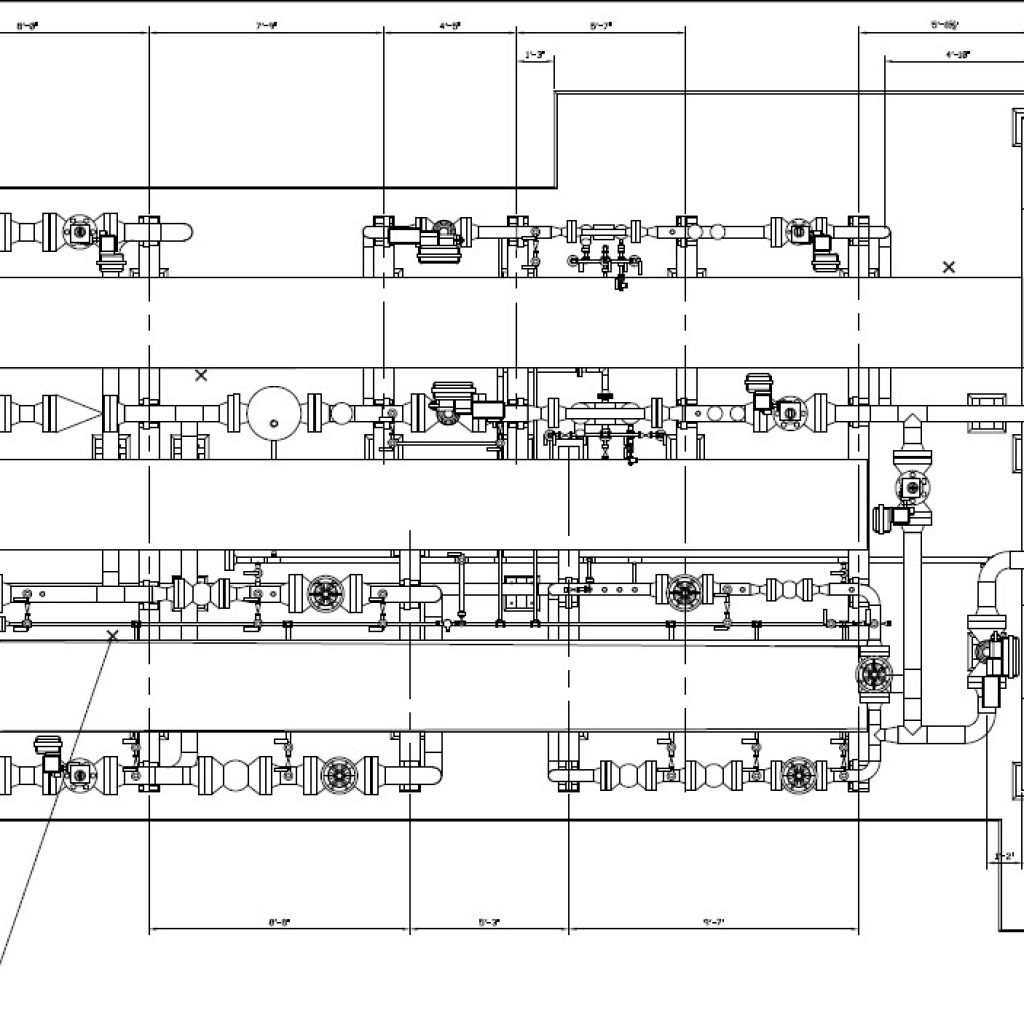

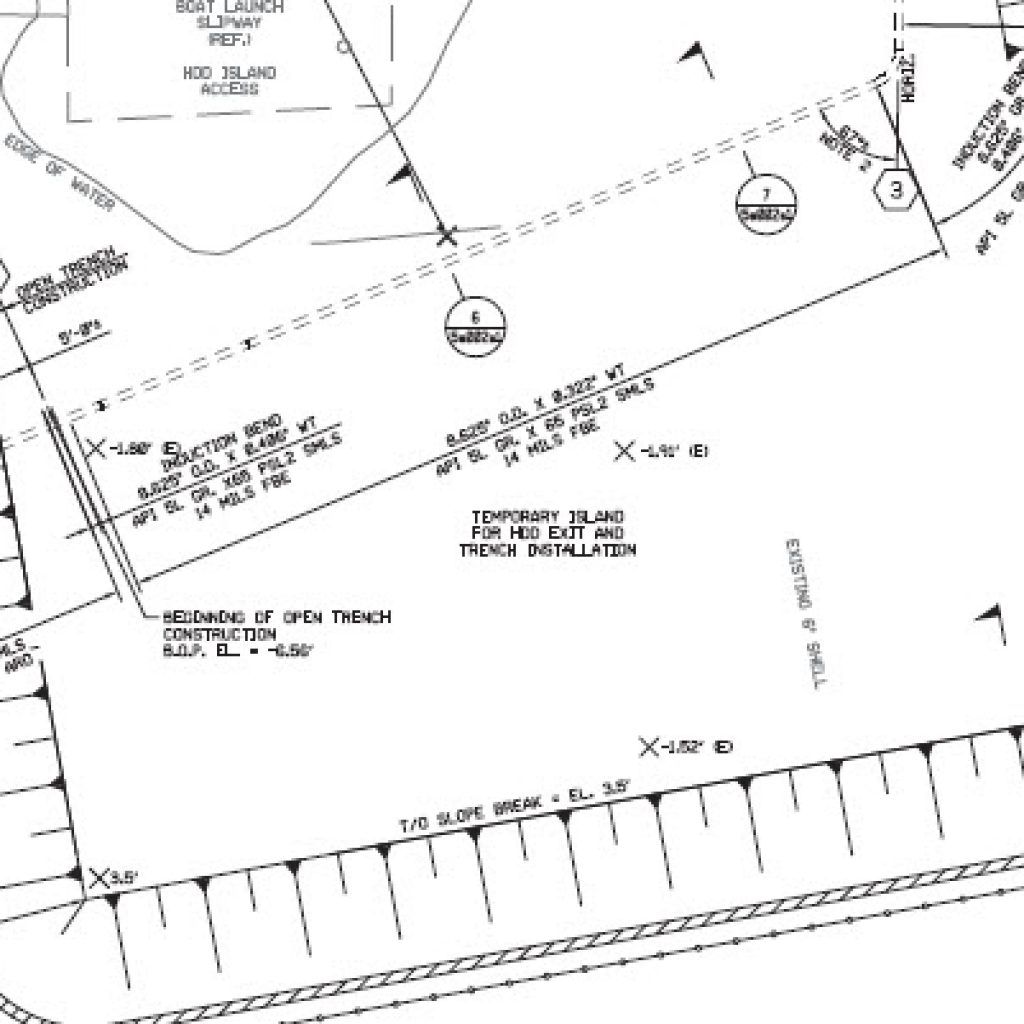

SPEC was involved in permitting; conversion of a public road into a private road; rehabilitation of the dock, including new marine dock arms and piping interconnections to the ship and barge facilities; new marine vapor destruction units and safety skids; design of multiple new manifolds to all sources and destinations; dedicated suction and fill lines for each tank to integrated manifolds; conversion of multiple existing tanks to different products; gas and blending; pump design and installation; connection to a pipeline; power distribution; dike containment; and installation of a new rail system. SPEC introduced laser scanning to the client to provide 3D modeling of the site, improving the site drawings and aiding in understanding of the design.

Services Provided: Project Development, Engineering, Design, Procurement and Permitting

Client: Major Oil Company

Project Location: Northeast, USA