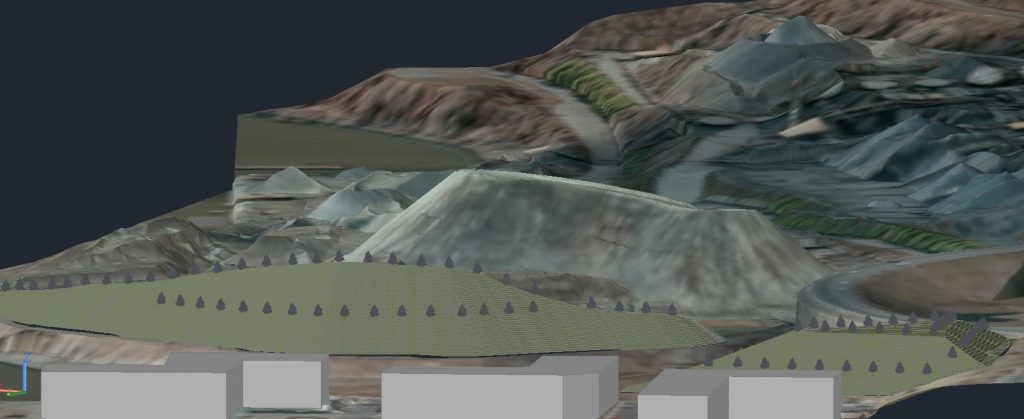

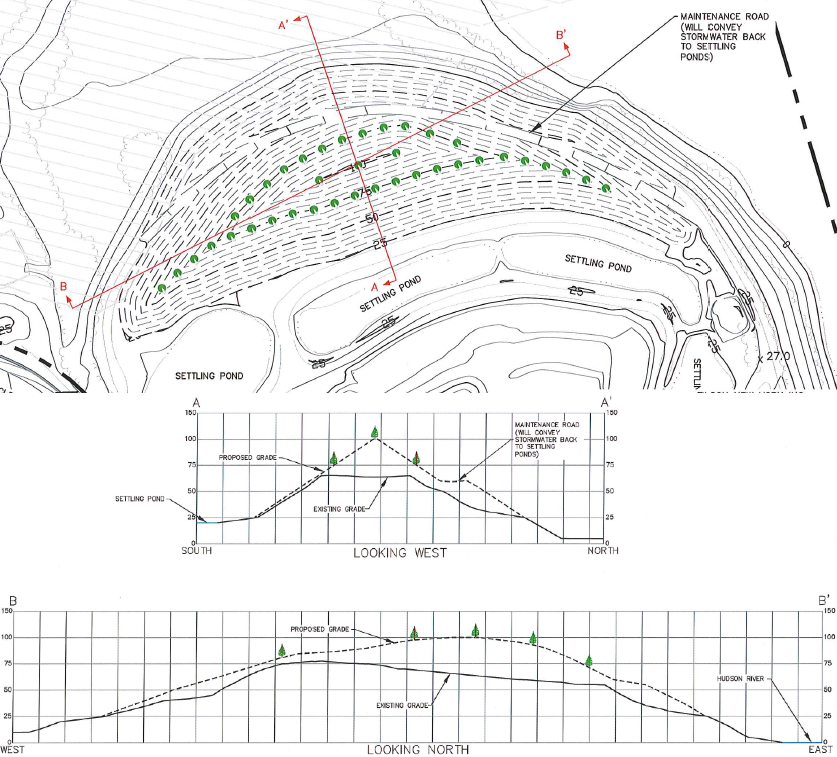

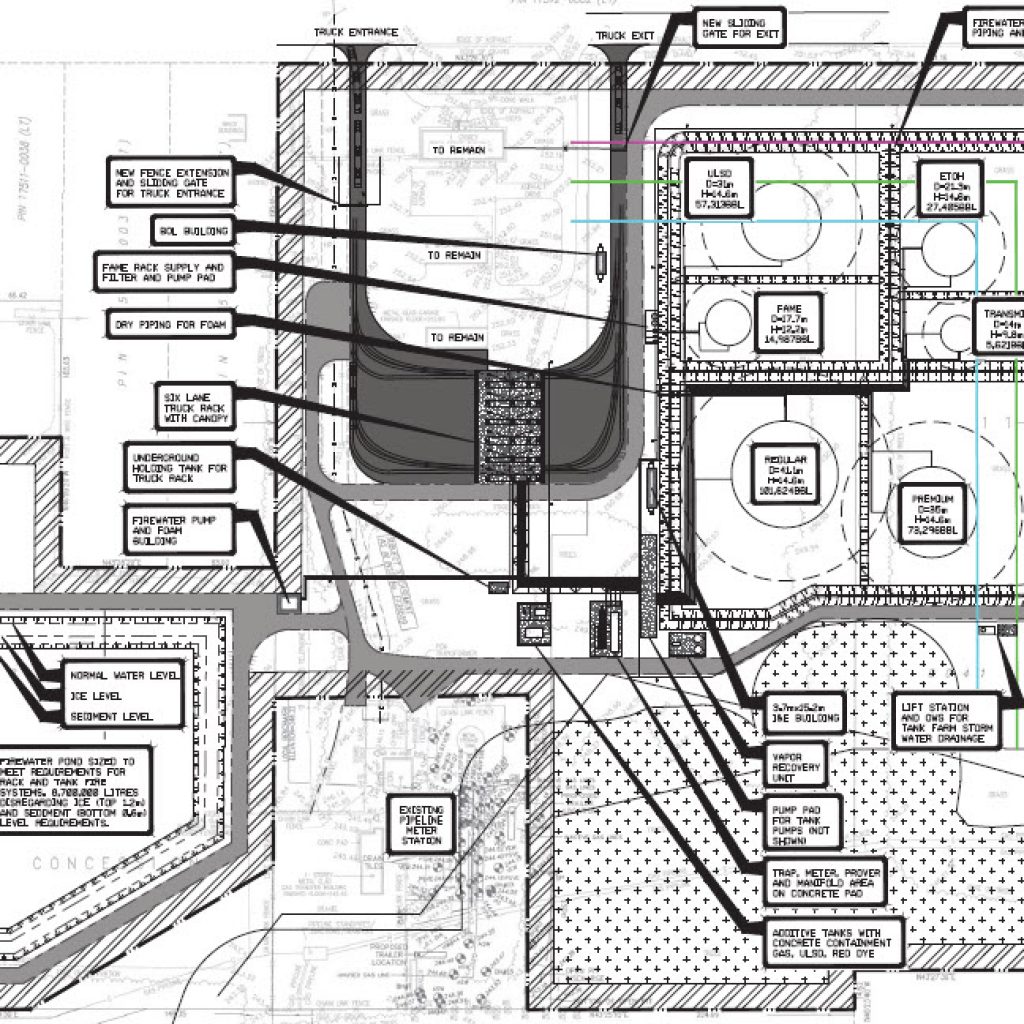

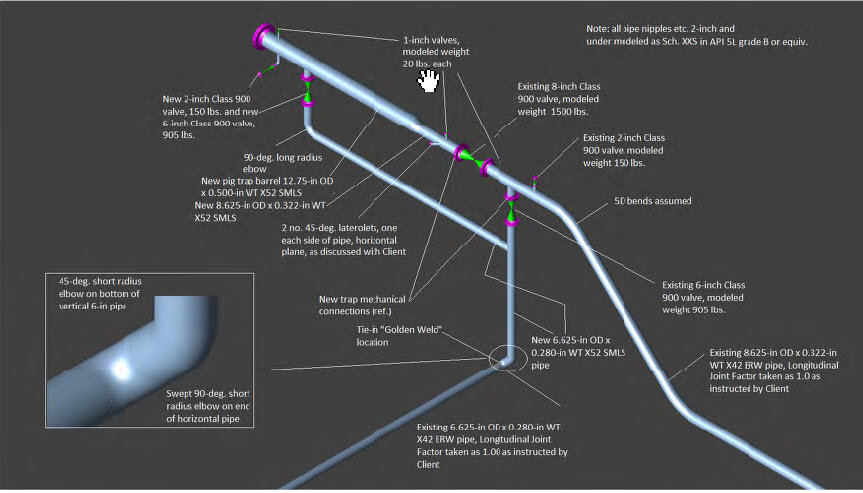

SPEC provided engineering, design, and support services for a client to resolve regulatory and ongoing operational concerns. The project required rectifying stormwater, visual and waste/overburden storage concerns. SPEC satisfied the regulatory requirements by using the overburden to rectify the visual concerns and addressed the stormwater issues at the site. SPEC designed the site grading layout and stormwater systems to meet local and state requirements on a geometrically and topographically constrained site. SPEC served as the primary point of contact for the local municipality, state, and federal regulators.

Services Provided: Project Management and Design, Civil/Structural Engineering, Design and Drafting, Permitting.

Client: Minerals, Mining, and Construction Materials Corporation

Project Location: Northeast, USA